I. About Us

The Department of Road & Bridge Engineering at Huazhong University of Science & Technology (HUST) was founded in 2000. Before then, it was part of the Department of Urban Construction in the former Wuhan Urban Construction College, one of the three universities/colleges merged to form the new HUST. Professor Guoding Wang, a renowned bridge expert, was the first head of the department. Currently, both Master’s and Doctoral Degrees are awarded in three areas: bridge & tunnel engineering, road & railway engineering, and geotechnical & underground structural engineering. There are three teaching and research sections in the department, i.e., road, bridge and geotechnical engineering teaching and research sections.

The Department of Road & Bridge Engineering at Huazhong University of Science & Technology (HUST) was founded in 2000. Before then, it was part of the Department of Urban Construction in the former Wuhan Urban Construction College, one of the three universities/colleges merged to form the new HUST. Professor Guoding Wang, a renowned bridge expert, was the first head of the department. Currently, both Master’s and Doctoral Degrees are awarded in three areas: bridge & tunnel engineering, road & railway engineering, and geotechnical & underground structural engineering. There are three teaching and research sections in the department, i.e., road, bridge and geotechnical engineering teaching and research sections.

There are currently more than 30 faculty and staff members in the department, including 13 professors, 11 associate professors and more than 5 lecturers. Among them, 25 possess Doctoral Degrees.

II. Research Areas

1. Theories and methodologies for assessment and design of geotechnical aspects of buildings and infrastructures over/in soft ground

Group members: Zheng Junjie; Liu Huabei; Wang Huabin; Li Xiaoqing; Gong Wenhui; Wang Xuefeng; Luo Xiaohui; Zhang Rongjun; Xu Dongsheng; Pu Hefu

Focuses on:

(1) Settlement control techniques and mechanism of high-speed railway / expressway embankments over soft ground;

(2) Ground improvement techniques for super-soft clayey ground;

(3) Design theories for reinforced soil structures;

(4) Design methodologies of building / infrastructure foundations in complex soft ground;

(5) Development of land reclamation technologies using dredged marine sediments as filling material;

(6) MICP technology for the improvement of granular material;

(7) Probability-based design methodologies for geotechnical engineering

2. Disaster prevention and mitigation of geotechnical engineering

Group members: Liu Huabei; Wang Huabin; Gong Wenhui; Miao Yu; Chen Hongjiang; Xu Dongsheng; Zhou Bo; Zhang Guangyong; Xu Hui

Focuses on:

(1) Risk assessment and control of landslide / debris flow;

(2) Evaluation on the seismic performance of geotechnical engineering such as reinforced retaining walls, pile foundations and underground structures etc.

(3) Intelligent monitoring of landslide / debris flow;

(4) Assessment and treatment of ground liquefaction

3. Design and analysis methodologies of tunnels and other underground structures in complex ground/environmental conditions

Group members: Wang Huabin; Gong Wenhui; Zheng Junjie; Li Xiaoqing; Xu Hui; Zhang Rongjun; Luo Xiaohui; Zhou Bo

Focuses on:

(1) Evaluation and control of environmental effect induced by soil excavation;

(2) Design theories and methodologies for large-scale underground structures;

(3) Construction technologies and design methodologies for tunnels in complex strata (e.g. soft rock, extremely high geostress condition, colluvial deposit, special soil, etc.);

(4) Dewatering and support of deep excavations under complex hydrological condition.

4. Mechanism/control of contaminant transport in landfill projects and remediation/reuse of contaminated soils

Group members: Zheng Junjie; Pu Hefu;Zhang Rongjun; Miao Yu

Focuses on:

(1) Landfill related geotechnical problems such as coupling of soil consolidation and contaminant transport;

(2) Solidification of dredged marine clay/lacustrine sludge;

(3) Remediation and reuse of contaminated soils;

(4) Development of sustainable landfill system.

5. New numerical methods in geotechnical engineering and micro soil mechanics

Group members: Miao Yu; Zheng Junjie; Zhou Bo; Wang Huabin; Liu Huabei; Gong Wenhui; Zhang Rongjun; Pu Hefu

Focuses on:

(1) Rapid large-scale numerical simulation methods;

(2) Large scale parallel computing;

(3) Micro soil mechanics and DEM.

6. Structural Theory of Bridges

Group members: Chen Zhijun; Fan Jianping; Jin Wencheng; Gao Rongxiong; Hu Jun; Liao Bihai; Zhu Aizhu; Hu liang; Sun Yuan

Focuses on:

(1) Structural system optimization on long span bridges;

(2) Development of new types of bridge systems;

(3) Earthquake resistant design of bridge engineering based on performance;

(4) Bridge design based on life-cycle theory considering redundancy and resilience;

(5) Refine analysis and multi-scale modeling of complicated bridge structure;

(6) Advanced material bridge structure

7. Dynamic behavior of high-speed railway bridge

Group members: Fan Jianping; Chen Zhijun;Zhu Aizhu; Hu liang; Sun Yuan

Focuses on:

(1) Vibration analysis on vehicle-rail-bridge coupling system;

(2) Vibration isolation and energy dissipation of high-speed railway bridge.

8. Condition Assessment, Maintaining and Retrofitting of Bridge infrastructure

Group members: Gao Rongxiong; Jin Wencheng; Hu Jun; Liao Bihai; Zhu Aizhu; Sun Yuan

Focuses on:

(1) Structural health monitoring of bridge infrastructure;

(2) Damage and deterioration of bridge Engineering;

(3) Condition assessment, life –cycle assessment and forecasting on bridge engineering;

(4) Detection and diagnosis technology;

(5) Maintenance decision-making.

9. Theories of road planning and road network design

Group members: Wu Ruilin; Zi Jianmin; Zhou Wujun; Zhang Xianyong

Focuses on:

(1) Assessment of traffic capacity of expressways / unban arterial roads;

(2) Theories of road planning and road network design;

(3) Intersection design of urban roads.

10. Design and assessment methodologies for subgrades and pavements of highways

Group members: Zi Jianmin; Wu Ruilin; Li Xiaoqing; He Lijiang; Luo Hui; Zhou Wujun; Zhang Xianyong

Focuses on:

(1) Testing and evaluating methods of subgrade and pavement structures;

(2) Design methodologies for subgrades and pavements of expressways;

(3) Asphalt pavement structures.

11. Development of new types of pavement materials

Group members: Li Xiaoqing; Wu Ruilin; He Lijiang; Zhou Wujun; Zhang Xianyong

Focuses on:

(1) New types of pavement materials;

(2) Recycling of old asphalt pavement materials;

(3) Construction technologies for road pavements involving new materials.

III. Introduction of laboratories

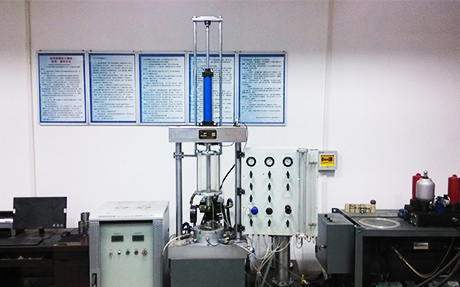

Geotechnical Engineering Laboratory:

The geotechnical engineering laboratory has the following devices:

1. Large-scale direct shear test system

The laboratory has a Cyclic ShearTrac System, which is a universal, large-scale shear system capable of performing the consolidation, cyclic shear, and static shear phases of a direct simple shear test under full automatic control. It can also perform large direct shear for studying the interface behavior of geotextile or soil-structure interface. The system consists of a computer controlled unit that utilizes micro-stepper motors to apply the vertical and both static and cyclic horizontal loads to the soil specimen.

2. Cyclic triaxial test system

The laboratory has a dynamic triaxial testing device, which can be utilized to determine the shear modulus (G) and damping ratio (D) of soils in either undisturbed or reconstituted states by using either load or displacement controlled cyclic triaxial system. The cyclic triaxial test is applicable to both fine grained and coarse grained soils. It is also used to study the liquefaction characteristics of silty and sandy soils.

3. Temperature controlled creep test system

The laboratory has a creep test machine which is a temperature controlled, creep test system capable of performing tensile and compression creep test under full automatic control. It contains three test devices for three independent tests. The system consists of a computer controlled unit that utilizes micro-stepper motors to apply the vertical loads. The uninterruptible power system can support the whole system continuous work for more than 3000 hours.

4. Conventional triaxial test devices

The laboratory consists of four triaxial testing systems which can be used for conventional triaxial tests (CU, CD, UU) as well as isotropic / anisotropic consolidation tests. Each triaxial testing system includes a closed-loop controlled load frame, automatic strain controlling unit, volume measuring/controlling unit, data acquisition system, transducers and different software solutions.

5. Conventional oedometer test devices

The laboratory has a number of oedometer testing equipments. Each of them consists of a set of consolidation device (including ring, porous stones, water reservoir, and load plate), Dial gauge (0.0001 inch = 1.0 on dial), sample trimming device, glass plate, metal straight edge, clock, moisture can, and filter paper. The standard oedometer consolidation test for saturated clays is the main feature of this experiment. The test is carried out by applying a sequence of vertical loads to a laterally confined specimen. The vertical compression under each load is observed over a period of time, usually up to 24 hours. Since no lateral deformation is allowed it is a one-dimensional test, from which the one-dimensional consolidation parameters are derived.

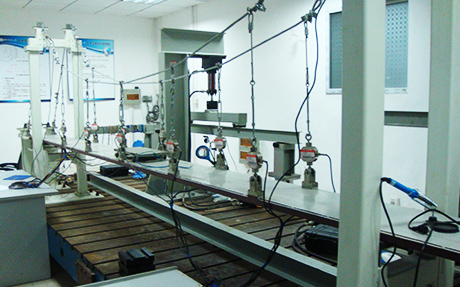

Bridge Engineering laboratory:

The bridge engineering laboratory has the following devices:

1. Large span bridge static and dynamic tests

The laboratory has suspension and cable-stayed bridge models. All of cables are mounted with tension transducers. To change situation of cables and install different sensors, static & dynamic tests can be conducted in this lab.

2. Structural member compression and shear test device

The laboratory has a compression and shear test instrument. Structural components, which are subjected to pressure and shear forces simultaneously, can be tested to capture the responses using this machine.

3. Test system for transverse loading of bridges

The laboratory has simply supported bridge models, which consists of 7 steel T-beams with 4.5m length and 1.2m width. Along the longitudinal direction, there are two loading points to simulate the moving loads. To measure strain and deflection, we can acquire the transverse distribution of loads.

Pavement Engineering laboratory:

The pavement engineering laboratory has the following devices:

1. System for asphalt concrete properties tests

The laboratory has two servo-hydraulic universal testing machine systems which can be used for the testing of asphalt concrete used in pavement construction, such as bending, creep and stress relaxation, and splitting test. The actuator is double-acting allowing both compressive and tensile forces to be applied, displacements can be measured by linear variable differential transformers and recorded. Temperature during the testing can be controlled with the programmable temperature cabinet.

2. Test system for asphalt concrete rut resistance

The laboratory has a asphalt concrete rut resistance testing machine system, rut depth can be measured by tracking a loaded wheel back and forth across an asphalt concrete sample for thousands of cycles.

11. Laboratory for asphalt mixture Marshall stability

The laboratory has a asphalt mixture Marshall stability and flow test setup, the resistance to plastic deformation of a compacted cylindrical asphalt mixture sample can be measured when sample is loaded diametrically.

12. Laboratory for aggregate toughness and abrasion characteristics

The laboratory has a Los Angeles abrasion testing equipment for evaluating the toughness and abrasion characteristics of aggregate used in asphalt concrete pavement construction.